Key information

- Location:

- Visit event website

- Event Date:

About this event

Introduction

Warehouses pose significant challenges when designing wireless networks due to factors like size, racking layout, material handling equipment (MHE), varying inventory levels, Wireless Access Point (WAP) mounting challenges, and fluctuating temperature and humidity. Overcoming these challenges requires experienced wireless professionals, considering the WLAN as a holistic system, and involving all stakeholders from the outset to ensure business outcomes are defined and understood.

Effective warehouse wireless design begins with understanding the use case requirements. Key considerations include:

- On-premises or cloud-based managed solutions: Determine whether your solution will be on-premises or fully managed in the cloud.

- WAP capabilities: Are you aiming to utilise the new 6GHz spectrum by using Wi-Fi 6E or Wi-Fi 7 Wireless Access Points (WAPs). Also are you going to be using WAPs with built-in BLE for location tracking?

- IT infrastructure support: Ensure your current IT infrastructure supports modern WAPs, which typically require at least POE+ (802.3at up to 30W) switches or even POE++ (802.3bt up to 60W) for advanced models.

Pre-Planning

Design Best Practices

Coverage Without Interference

With the 6GHz spectrum now available, you have an additional 24 x 20MHz channels. To maximise this, design your network to support both 5GHz and 6GHz devices.

Redundancy

Incorporate coverage redundancy into your WLAN design to avoid interruptions from WAP malfunctions. This is achieved by ensuring secondary coverage from a nearby WAP on a different channel, providing enough coverage for continued operations while the primary WAP is fixed.

Variable Inventory Levels and Types

Inventory levels and types can change frequently, impacting signal attenuation. Design your wireless network for peak inventory periods and consider the types of products that may be stored in the future to ensure consistent Wi-Fi coverage.

Particularly Challenging Areas in a Warehouse

High Racking and Very Narrow Aisles (VNA)

High racking and VNA areas present unique challenges. WAPs must be mounted high enough to avoid clashing with fully extended trucks and to ensure coverage reaches the ground. Use semi-directional antennas to direct the signal along the aisle, minimising interference with adjacent aisles.

Pick Mods/Towers

Pick modules, with their multiple floors and integrated shelves, pose challenges for RF signals due to metal floors, ceilings, and walls. These areas often experience reflection, diffraction, and refraction, leading to performance issues. Ensure WAPs provide coverage down the aisles and have enough signal strength to reach adjacent aisles without causing interference.

Robotics and Automation

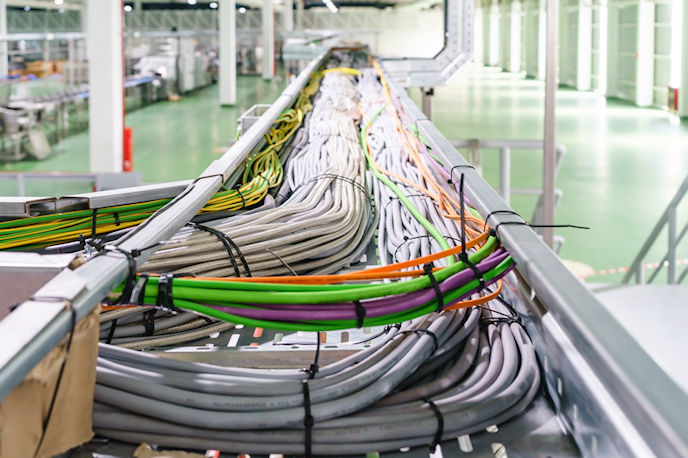

Warehouse automation requires careful design to handle robots moving long distances and at significant speeds. Ensure your Wi-Fi design supports seamless roaming for robots and avoids non-Wi-Fi noise from conveyors that can impact the Signal-to-Noise Ratio.

Humidity

High humidity can affect wireless signals and damage WAPs. Use WAPs designed for outdoor usage or NEMA-certified enclosures for full moisture protection, considering the extra attenuation caused by moisture in the air.

Installation

Ensure WAP installation is performed by companies who can offer a 25-year system warranty on the cabling infrastructure. Your wireless infrastructure designers should present the design to installers in AutoCAD format with detailed WAP positioning and mounting instructions, complying with health and safety regulations and Building Information Modelling (BIM) standards.

User Devices

Consider the entire wireless system, including end-user devices like wireless handheld scanners. Ensure devices support the latest Wi-Fi protocols and technologies, including:

- 5GHz and 6Ghz support. (Wi-Fi 6E and Wi-Fi 7)

- Fast BSS Transition (802.11r)

- Assisted Roaming (802.11k)

- Network Assisted Power Savings (802.11v)

- At least 2×2 MU-MIMO for improved throughput

Validation Surveys and Ongoing Support

After installation, conduct an RF validation survey to assess Wi-Fi coverage, Signal to Noise Ratio (SNR), WAP redundancy, and overall network health. This should be done once inventory levels exceed 70% capacity and ideally on an annual basis. Consider the current WLAN layout whenever racking is moved or changed to maintain optimal Wi-Fi performance.

About Us

Dynamic Technologies Europe (DTE) is a leading provider of Wi-Fi services, core & operational IT hardware, and smart warehousing solutions. We help warehousing and logistics facilities overcome wireless challenges, achieve operational efficiencies, build robust IT networks, and ensure automation readiness. Discover how DTE can make your wireless network ready for the future by visiting our site at www.dteonline.com